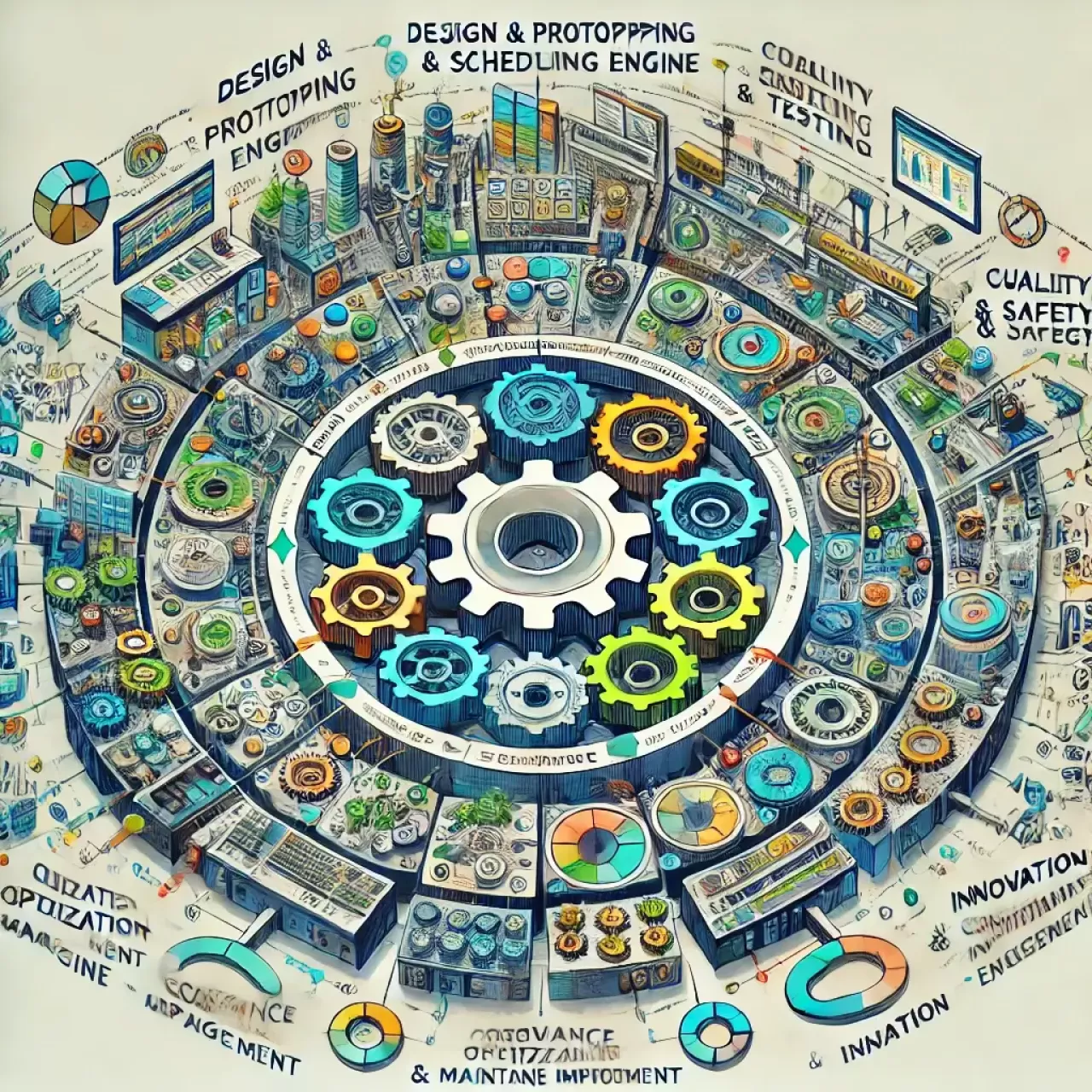

What is Engineering Work Engine Execution Ecosystem (E-WEEE)?

The Engineering Work Engine Execution Ecosystem (E-WEEE) is a specialized, structured framework aimed at enhancing the efficiency, quality, and productivity of engineering operations. Through modular “work engines,” E-WEEE organizes the entire engineering lifecycle—from concept and design to testing, compliance, and maintenance—enabling organizations to manage complex projects, optimize resources, and innovate effectively.

Core Elements of the Engineering Work Engine Execution Ecosystem (E-WEEE)

1. Engineering Work Engine Modules

Each module in E-WEEE is designed to handle critical aspects of the engineering lifecycle:

-

Design & Prototyping Engine

Manages the creation of design specifications and prototypes.- Enables CAD modeling, iterative design, and prototype testing.

- Streamlines feedback integration and promotes collaborative development.

-

Project Management & Scheduling Engine

Tracks project timelines, tasks, and resource allocation.- Supports Gantt charts, agile boards, and resource planning.

- Ensures adherence to milestones and facilitates efficient task distribution.

-

Quality Assurance & Testing Engine

Ensures product quality and reliability throughout development.- Conducts automated and manual tests, defect analysis, and quality checks.

- Tracks compliance with standards and industry requirements.

-

Compliance & Safety Management Engine

Oversees regulatory and safety adherence.- Manages safety protocols, risk assessments, and certification processes.

- Integrates compliance tracking with international standards like ISO.

-

Lifecycle & Maintenance Management Engine

Manages product lifecycle, maintenance, and upgrades.- Tracks maintenance schedules, service records, and EOL planning.

- Ensures reliability and extends product lifespan with data-driven insights.

-

Resource Optimization & Cost Management Engine

Optimizes resource allocation and cost control.- Monitors resource usage, prevents bottlenecks, and forecasts costs.

- Supports strategic resource management and expense tracking.

-

Innovation & Continuous Improvement Engine

Drives iterative improvement and knowledge sharing.- Collects insights, tracks improvement suggestions, and supports R&D.

- Implements small but impactful changes to boost efficiency and reduce waste.

-

Data Analytics & Insights Engine

Aggregates and analyzes engineering performance data.- Monitors KPIs, cycle times, and productivity metrics.

- Uses predictive analytics to inform design, development, and optimization.

2. Cross-Functional Execution Layers

E-WEEE's layers create an integrated and adaptable structure across modules:

- Strategic Layer: Aligns engineering objectives with organizational goals, focusing on long-term performance and innovation.

- Operational Layer: Oversees daily activities within each engine, ensuring productivity and adherence to timelines.

- Analytical Layer: Monitors and adjusts performance based on real-time metrics, KPIs, and operational feedback.

3. Collaboration and Integration Network

E-WEEE's collaboration network enhances team communication and project coordination:

- Internal Communication Tools: Connects teams for real-time updates, shared resources, and feedback.

- Vendor and Supplier Integration: Manages partnerships with suppliers for components, materials, and outsourced services.

- Stakeholder Feedback Mechanisms: Collects input from clients, end-users, and stakeholders to improve product development.

Execution Framework for E-WEEE

- Goal Setting and Strategy Development: Defines engineering objectives and aligns them with resource requirements.

- Standardization and Automation of Processes: Establishes repeatable workflows and automates recurring tasks, such as testing protocols.

- Real-Time Tracking and Adaptation: Monitors metrics like cycle time, defects, and resource utilization to make immediate adjustments.

- Continuous Evaluation and Improvement: Regularly assesses module performance and adapts to changing requirements and feedback.

Technology and Tools for E-WEEE

- Computer-Aided Design (CAD) Software: Essential for designing and modeling products.

- Project Management Platforms: Tools like MS Project, Asana, or Trello for task tracking and resource allocation.

- Quality Management Systems (QMS): To track and manage quality compliance and documentation.

- Analytics Platforms: Tools for data analysis and performance tracking, offering insights into project health and productivity.

Benefits of E-WEEE

- Increased Efficiency: Automates repetitive processes, saving time and reducing delays in project timelines.

- Enhanced Quality and Compliance: Ensures adherence to industry standards and reduces the risk of defects.

- Resource Optimization: Balances resource demands, preventing bottlenecks and minimizing costs.

- Data-Driven Engineering Decisions: Analytics provide actionable insights that drive innovation and continuous improvement.

- Risk Reduction: Compliance and safety protocols reduce the likelihood of project and operational risks.

Steps to Implement E-WEEE

- Assess Needs and Define Goals: Review current practices and set clear objectives for each engine.

- Deploy Core Engines: Implement foundational modules, including Design & Prototyping, Project Management, and QA Testing.

- Integrate Technology Solutions: Link ERP, CAD, and QMS systems to centralize data and streamline workflows.

- Provide Team Training: Equip teams with knowledge and tools to effectively utilize E-WEEE.

- Monitor Performance and Optimize: Regularly review each engine’s performance to make adjustments and enhancements.

Applications Across Engineering Sectors

- Manufacturing Engineering: Automates production planning, quality control, and lifecycle management.

- Infrastructure Projects: Supports project timelines, resource allocation, and regulatory compliance.

- Aerospace and Automotive: Ensures high standards in design, safety, and reliability for complex engineering projects.

Measuring Success in E-WEEE

Key metrics include:

- Cycle Time Reduction: Measures speed and efficiency improvements in the design-to-production pipeline.

- Defect Rates and Quality Scores: Tracks product reliability and adherence to quality standards.

- Resource Utilization Metrics: Evaluates how effectively resources are allocated.

- Compliance Rate: Monitors adherence to industry standards and safety protocols.

- Innovation Index: Assesses the frequency and impact of incremental improvements.

The Engineering Work Engine Execution Ecosystem (E-WEEE) is a comprehensive, adaptable framework for managing engineering projects efficiently. By organizing tasks through specialized work engines and leveraging data for continuous improvement, E-WEEE empowers organizations to enhance productivity, ensure compliance, and drive innovation in today’s competitive engineering landscape.

About The Author:-

Prakash Chand Sharma, a multi-talented leader, defies labels. He's a pioneer of "The Doctorate of Growth & Success" and the Work Engine Network. Sharma seamlessly blends expertise in engineering, law, finance, and business.

His academic background (visiting professor) combined with engineering, legal practice, and tax consultancy experience showcases his intellectual depth. Over a decade of entrepreneurship across various sectors, coupled with leadership positions in multiple companies, has honed his strategic vision.

This unique blend positions Sharma as a transformative leader and a sought-after mentor. His visionary leadership has driven the success of the Zumosun Group, a diversified conglomerate. His dedication to growth extends beyond business with his innovative "The Do.GS" concept.

Follow On:-

1. https://www.linkedin.com/in/eng-adv-ca-m-prakash-chand-sharma-26586143/

2. https://www.facebook.com/er.adv.ca.prakash.chandsharma.35